Salt Spray and Salt Fog Corrosion Test Chamber

Description

Basic Info.

| Model NO. | ZH-SH-60 |

| Warranty | 12 Months |

| Power | Electronic |

| Standard | ISO9227, ASTM B117, En 61000 |

| Test Type | Aass, Nss, Cass Optional |

| Certification | Ce, RoHS, FCC, ISO, SGS Certificates |

| Types | Digital Control / Touch-Screen |

| External Size | 108 X 108 X 65cm |

| Temperature Set | 35±1 °(Cass)50±1 |

| Inner Size | 60 X 45 X 40cm |

| Transport Package | Wooden Case for Export |

| Specification | Customization available |

| Trademark | Sailham |

| Origin | Guangdong, China |

| HS Code | 8479899990 |

| Production Capacity | 5000sets/Year |

Product Description

Salt Spray and Salt Fog Corrosion Test Chamber

Salt Spray chambers are commonly used to evaluate the corrosive properties of:Phosphated surfaces (with subsequent paint/primer/lacquer/rust preventive).Zinc and Zinc-alloy plating (see also electroplating).Electroplated chromium, nickel, copper and tin.Coatings not applied electrolytically (such as zinc flake coatings).Organic Coatings.Paint Coating.

Product specifications

| Model | ZH-SH-60 | ZH-SH-90 | ZH-SH-120 | ZH-SH-160 | ZH-SH-200 | ||||

| Internal Dimension WxHxD (mm) | 600x450x400 | 900x600x500 | 1200x800x500 | 1600x800x500 | 2000x1000x500 | ||||

| External Dimension WxHxD (mm) | 1100x600x1200 | 1400x950x1200 | 1900x1300x1400 | 2300x1300x1400 | 2700x1500x1500 | ||||

| Lab Temperature | Saline test (NSS ACSS) 35±1 °C; Corrosion Test (CASS)50±1 °C | ||||||||

| Pressure Bucket Temperature | Saline test method (NSS ACSS) 47±1 °C / Corrosion Test (CASS)63±1 °C | ||||||||

| Lab Capacity(L) | 110 | 270 | 500 | 800 | 1500 | ||||

| Saline Capacity(L) | 15 | 25 | 40 | 40 | 40 | ||||

| Saline Concentration | 5% concentration of NaCl, or every Liter 5% NaCl add 0.26g CuCl2H2O | ||||||||

| Exter./Inter.Material | P.V.C & P.P | ||||||||

| Compressed Air Pressure(Kgf) | 1.0~6.0 | ||||||||

| Spray Volume | 1.0~2.0ml /80cm2 /h(working at least 16 hours, and take the average value) | ||||||||

| Spray Form | Continuous Spraying or Programmable Spraying | ||||||||

| Power | AC220V , lines15A | ||||||||

| Weight(Kg) | 65 | 80 | 120 | 160 | 200 | ||||

| System | Salt Spray Vehicle | Air+acid(base)liquid | |||||||

| Heating | SUS#304 & #316stainless steel heater+taflon | ||||||||

| Controller | Hydrometer,salinomerer,fog collector,glassbar | ||||||||

| Safety Devices | Overheating prevention circult-breaker,dehydration and overheating prevention mechanism,breakdown indicator light | ||||||||

| Power Source(K.W.) | AC 1Ψ 220V 60/50Hz | ||||||||

| 1.1 | 1.5 | 3.5 | 5.5 | 7 | |||||

Structure

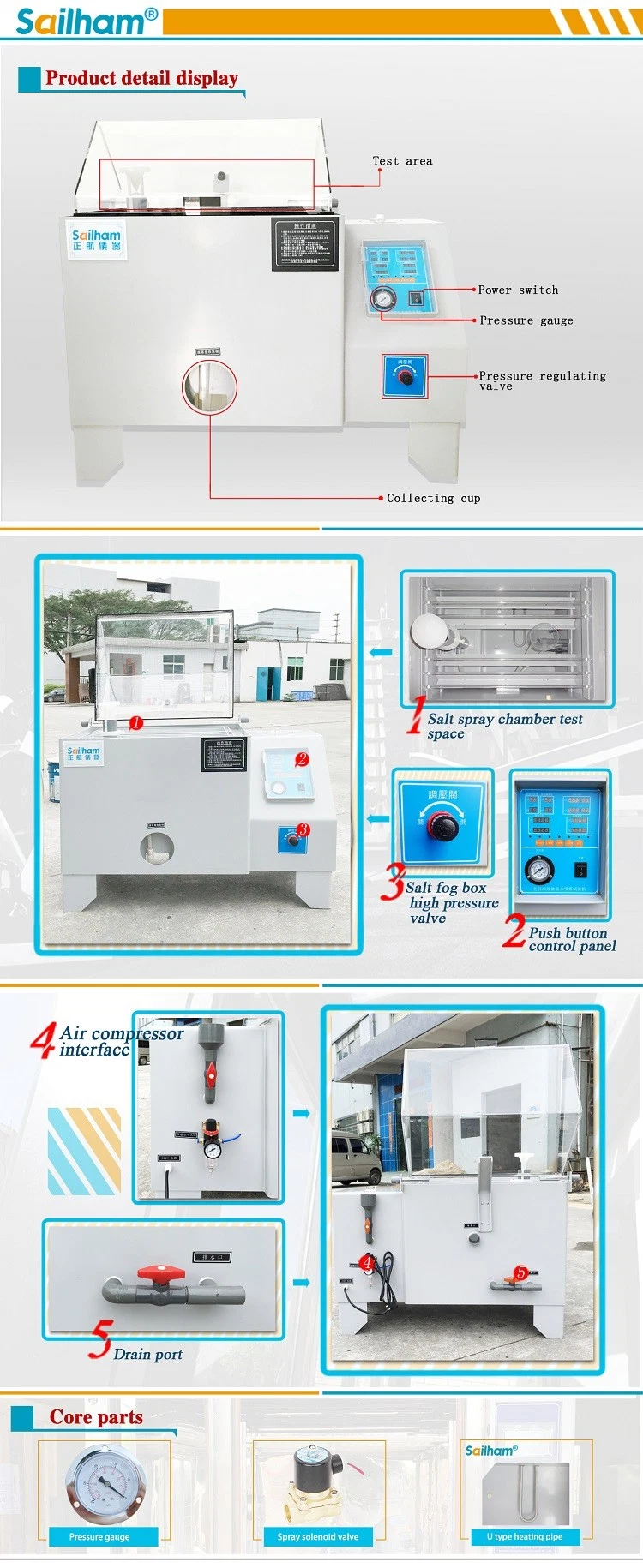

1. The Salt Spray and Salt Fog Corrosion Test Chamber cover is made of transparent materials so that the operator can see the tested sample in the chamber and the spraying situation of the tested sample.2. A waterproof structure is adopted between the chamber cover and chamber body and thus there is no salt spray overflow.3. Adopts the tower spraying system and equipped with the salt solution filter system and non-crystal nozzle so as to realize even salt spray distribution and freely adjustable settlement.4. Entire PP&PVC solid mechanical structure, resistance to hydrochloric acid, heat resistance and never aging, suitable for salt fog copper acetate, etc.5. Patent nozzle and conical diffusion device makes the fall fog rapidly and evenly. With manual level automatic control mode, the biggest setting time can reach 9990 hours.6. With automatic demist device, it can clear observe the tested products after the experience is finished.7. Three complete temperature control systems (Saturated air temperature, temperature inside the chamber, test liquid temperature) ensure the consistency and standards of the test.

Company profile

With more than 14 years of experience.Sailham is a leading manufactuer that specializes in manufacturing and marketing the cost effective& nbsp;and reliable environmental test chambers. Our main products includes:environmental test equipment and mechanical/optical equipment,such as:programmable constant temperature humidity test chamber, high - low temperature cycling test chamber,thermal shock test machine(2zone or 3zone)...Sailham have got the international advanced ISO9001: 2008 quality management system certification,FCC certification, RoHS certification and SGS certification and also got the nationalhigh-tech enterprise certificate.Sailham work with many greatest company in the different industries in the world and provied the professional service

Our Factory

Our Workshop.

Packaging and shipping

FAQ

Q: What's the payment term?

A: T/T, L/C and other payment terms could be negotiated.

Q:Do you accept customization service?

A:Yes, of course, we can not only offer standard High and Low Temperature Alternating Damp Heat Testing Chamber, but also customized machines according to your request. Don't hesitate to tell us your requirement, we will try our best to meet your needs.

Q:How about your warranty?

A:Generally, our warranty is one year. Within the warranty period, we can offer technique support, Feedback to you within 24 hours and help you to repair your problem controller freely, even it's not from our factory

Q:Can we visit your factory before order?

A:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q: What's the delivery term?

A:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q:How about the packing for machine, is it safely protected during transportation?

A: Testing Chamber is packed by standard export wooden box for outside package and stretch film for inner package, it won't be damaged. We've delivered many testing machines abroad by sea or by air without damage.

Contact US

Tel :+86-769-81105095 Fax:+86-769-22400804Website :sailham.en.made-in-china.com Company Address:1612 Huiyi Fortune Center Building, Intersection of Bulong Rd. and Longguan Rd., Longhua new district, Shenzhen, Guangdong, ChinaFactory Address: NO.53,Jin Yuan Xin Road,Shi Long Keng,Liao Bu Town. Donggaun. Guangdong China (Mainland)

Prev: Xenon Arc Lamp Aging Test Chamber for Solar Simulation Test

Next: Temperature and Humidity Intelligent Digital Temperature Controller Xm

Our Contact