Komeg Manufacturer Walk in Constant Temperature and Humidity Chambers

KOMEG Manufacturer Walk in Constant Temperature and Humidity Chambers The Brand of the parts we use: Why Customers Choos

Description

Basic Info.

| Model NO. | KMHW-8L |

| Function | for Big Specimen Testing |

| Sample Holder | Can Be Customized |

| Inner Size | W2000*H2000*D2000mm |

| Temp. Constancy | +/-0.5oc |

| Humidity Uniformity | +/-3.0%R.H. |

| Humidity Constancy | +/-2.5%R.H. |

| Humidity Range | 20-98%R.H. |

| Temp. Range | -40oc~+150oc or -104of~+302of |

| Transport Package | Strong Plywood Case, Meet International Standards |

| Specification | Standard and Customized |

| Trademark | KOMEG |

| Origin | Dongguan, China |

| HS Code | 90321000 |

| Production Capacity | 1000 Sets Per Yesr |

Product Description

KOMEG Manufacturer Walk in Constant Temperature and Humidity Chambers

The Brand of the parts we use:

Why Customers Choose KOMEG?

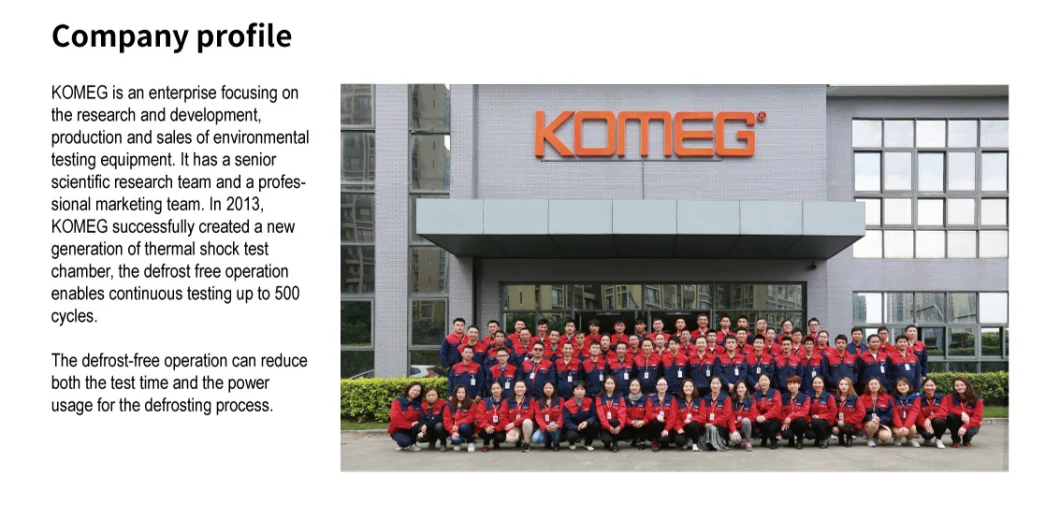

1.Specializing in environmental test chamber for 26 years

2.Valued customers: HUAWEI, TCL, EMERSON, OMRON, GREE, SGS,FOXCONN,etc.

3.Imported Tecumseh or Danfoss compressor

4.LED Touch Screen Controller

5.One year free parts warranty

| Environmental Temperature and Humidity Chamber | ||||||

| Secifications ( at +20°C room temp. Or+25°C water temp with empty load) | ||||||

| Model | KMH-L series | |||||

| 150L | 225L | 408L | 800L | 1000L | ||

| Interior sizel | W(mm) | 600 | 700 | 700 | 1000 | 1000 |

| H(mm) | 600 | 700 | 750 | 1000 | 1000 | |

| D(mm) | 460 | 480 | 800 | 800 | 1000 | |

| Exterior size | W(mm) | 880 | 980 | 980 | 1280 | 1280 |

| H(mm) | 1730 | 1890 | 1940 | 2160 | 2160 | |

| D(mm) | 1400 | 1460 | 1740 | 1750 | 1950 | |

| Weight(KG) | 250 | 300 | 420 | 530 | 600 | |

| Temp. range | -40 °C ~ +150°C | |||||

| Humidity Range | 20 ~ 98&R.H. | |||||

| Temp. constancy | ±0.5ºC | |||||

| Humidity constancy | ±2.5%R.H | |||||

| Humidity uniformity | ±3.0 % R.H | ±5.0 % R.H | ||||

| Heat up time | -40°C ~+100°C , within 45 min | |||||

| Pull down time | +20°C ~ -40°C , within 60 min | |||||

| Equipment Power | 7.5 | 7.5 | 8.5 | 14.5 | 14.5 | |

| Ambient Temp. | 5ºC ~+35ºC | |||||

| Standard accessories | Sight window*1, cable port(portΦ50mm)*1, shelves*2, chamber lamp*1, power cable *2m | |||||

| Safety device (standard) | No fuse breaker, over pressure \ over heat and over current protection for compressor, Over temp. protect, over load protect of blower, dry heat protection | |||||

| Control System | Balanced Temperature & Humidity Control System | |||||

| Refrigeration system | Air Cooled ( Water Cooled Type is option ) | |||||

| Hermetic compressor,Single stage refrigeration system, CFC-Free refrigerant(HFC-507/HFC-23) | ||||||

| Controller | Panel:7-inch LCD Touch panel, Chinese or English display selectable | |||||

| Operation model :Program or fix point running | ||||||

| Memory capacity :120programs,1200steps, | ||||||

| All repeat 999 cycles, part repeat 99 cycles | ||||||

| Interior material | Stainless Steel Plate ( SUS 304 ) | |||||

| Exterior material | Baked Painting Steel Or Stainless steel(SUS304) | |||||

| Insulation material | Rigid polyurethane Foam and Glass Fiber Wool | |||||

| System | Balanced & Humidity Control System | |||||

| Wiring method | AC 380±10 % 50Hz ,3 phase 4 wires +Ground Wires | |||||

| Note: 1. We reserve the right to change specifications without prior notice 2. Customized sizes and configurations available | ||||||

How to maintain the environmental test chamber ?

When you are in an environmental chamber testing laboratory, You may need the environmental chamber insulation or environmental chamber testing services. The below are some guidance which may helpful for you when you are processing the environmental chambers repair work. Try to find local environmental test chamber manufacturers and inquiry their benchtop and walk in environmental chamber price is a good idea !

1. Water pipes in waterways are easy to block and leak. Please check regularly whether there is water leakage or water plugging. The stored water in the humidifier in the small environmental chamber shall be replaced once a month to ensure the water quality is clean and the flow is smooth.

2. When the test sample is taken out after the time is up, the environmental chamber for battery testing must be shut down and the staff must wear dry, electricity-proof and moisture-resistant gloves.

3. When opening and closing doors or taking test objects from the environmental chambers, Do not let the test samples touch the glue edge on the door, in case the glue edge is damaged and the service life is shortened.

4. The ground around environmental test chamber shall keep clean at all times to avoid accidents and performance degradation caused by dust inhalation into the unit.

5. The freezing system is the core of the environmental chamber. Please inspect all copper pipes once a year to see if there is any leakage of Freon. Please inform the environmental chamber factory in casa there any oil leakage of horn joints and welding joints.

Prev: Simulated Solar Radiation Environmental Xenon Lamp Resistance to Climate Test Chamber

Next: Vacuum Aging Drying Test Oven Chemical Industrial Test High Temperature Low Pressure Chamber

Our Contact

Send now