Automotive Components Cold Thermal Shock Test Chamber

Automotive components cold thermal shock test chamberThe main purpose• Using low temperature and high temperature therma

Description

Basic Info.

| Model NO. | UP-6118 |

| Applications | School, Hospital, Lab, Factory, Industry |

| Service | OEM / ODM / Non-Standard Available |

| Cooling Method | Air-Cooled Water-Cooled |

| Types | Basket-Type (2-Zone) or 3-Zone Optiona |

| Temp. Shock Range | -40c / -50c / -60c / -70c Optional ~+150c |

| Transport Package | Professional Export Packaging |

| Specification | 40L,80L,150L,225L,408L,800L,1000L or Customized |

| Origin | China |

| HS Code | 9024800000 |

| Production Capacity | 1000/Year |

Product Description

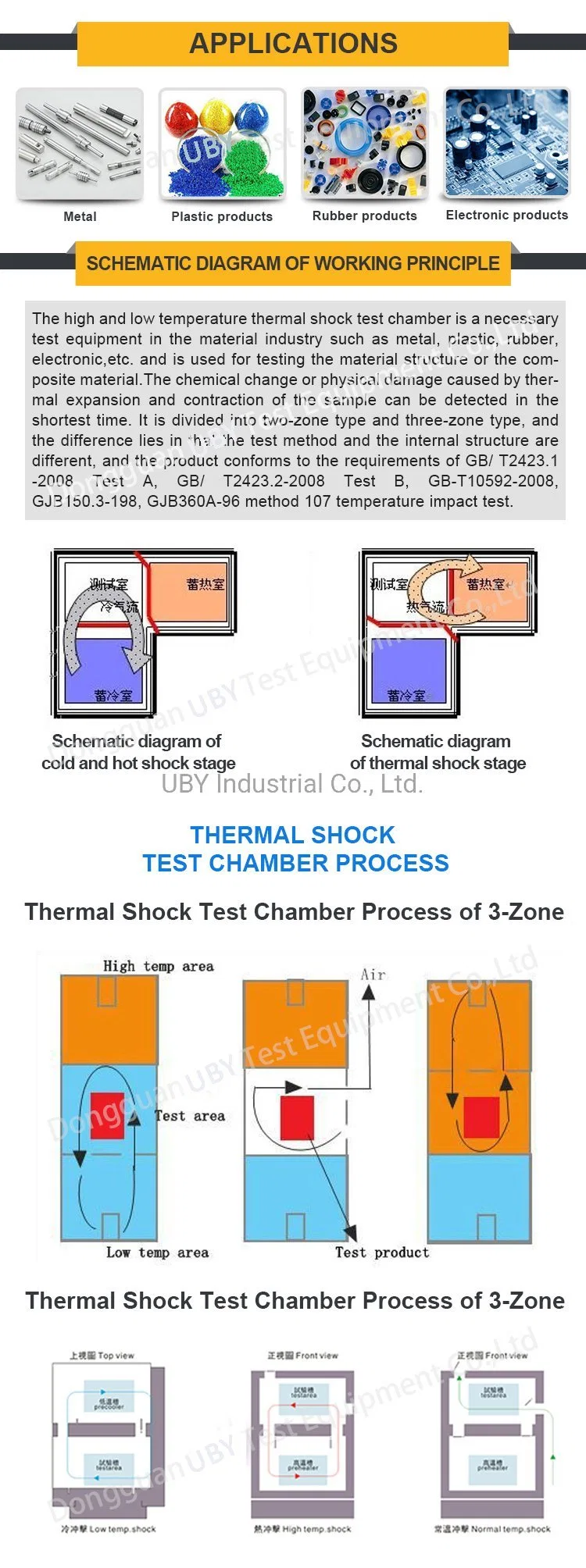

Automotive components cold thermal shock test chamberThe main purpose• Using low temperature and high temperature thermal storage tank, according to the cylinder valve action needs, high temperature energy and low temperature energy are sent to the test tank, so as to achieve rapid temperature shock effect, balance temperature control system (BTC) + specially designed air circulation The system uses PID to control SSR so that the heating capacity of the system is equal to the heat loss, so it can be used stably for a long time.| internal volume(L) | 49 | 80 | 100 | 150 | 252 | 480 | |

| size | Inter size: W×D×H(cm) | 35×40×35 | 50×40×40 | 50×40×50 | 60×50×50 | 70×60×60 | 80×60×85 |

| Outer size: W×D×H(cm) | 139×148×180 | 154×148×185 | 154×158×195 | 164×168×195 | 174×180×205 | 184×210×218 | |

| High greenhouse | +60ºC→+180ºC | ||||||

| Heating time | Heating up +60ºC→+180ºC≤25min Note: The heating time is the performance when the high-temperature room is operated alone | ||||||

| Low-temperature greenhouse | -60ºC→-10ºC | ||||||

| Cooling time | Cooling +20ºC→-60ºC≤60min Note: The rising and falling time is the performance when the high-temperature greenhouse is operated alone | ||||||

| Temperature shock range | (+60ºC±150ºC)→(-40ºC-10ºC) | ||||||

| performance | Temperature fluctuation | ±5.0ºC | |||||

| Temperature deviation | ±2.0ºC | ||||||

| Temperature recovery time | ≤5mm | ||||||

| Switching time | ≤10ses | ||||||

| noise | ≤65(db) | ||||||

| Simulated load | 1KG | 2KG | 3KG | 5KG | 8KG | 10KG | |

| Material | Shell material | Anti-rust treatment cold rolled steel plate + 2688 powder coating or SUS304 stainless steel | |||||

| Inner body material | Stainless steel plate (US304CP type, 2B polishing treatment) | ||||||

| Insulation Materials | Rigid polyurethane foam (for box body), glass wool (for box door) | ||||||

| Cooling System | Cooling method | Mechanical two-stage compression refrigeration method (air-cooled condenser or water-cooled heat exchanger) | |||||

| Chiller | French "Taikang" fully hermetic compressor or German "Bitzer" semi-hermetic compressor | ||||||

| Compressor cooling capacity | 3.0HP*2 | 4.0HP*2 | 4.0HP*2 | 6.0HP*2 | 7.0HP*2 | 10.0HP*2 | |

| Expansion mechanism | Electronic automatic expansion valve method or capillary method | ||||||

| Blower for mixing in the box | Long axis motor 375W*2 (Siemens) | Long axis motor 750W*2 (Siemens) | |||||

| Heater: | nickel-chromium alloy electric heating wire heater | ||||||

| Power Specifications | 380VAC3Φ4W50/60HZ | ||||||

| AC380V | 20 | 23.5 | 23.5 | 26.5 | 31.5 | 35 .0 | |

| Weight (kg) | 500 | 525 | 545 | 560 | 700 | 730 | |

Product Paramenters

Our service:

During the whole business process, we offer Consultative Selling service.

1)Customer inquiry process:

Discussing testing requirements and technical details, suggested suitable products to customer to confirm.

Then quote the most suitable price according to customer requirements.

2)Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photos to show the appearance of the product. Then, confirm the final solution and confirm the final price with the customer.

3)Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photos to show the production process.

After finishing production, offer photos to the customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products is confirmed shipping time and inform the customer.

4)Installation and after-sale service:

Defines installing those products in the field and providing after-sales support.

FAQ:

1. Are you a Manufacturer? Do you offer after-sales service? How can I ask for that? And how about the warranty?

Yes, we are the one of professional Manufacturers like Environmental Chambers, Leather shoe testing equipment, Plastic Rubber testing Equipment... in China. Every machine purchased from our factory has 12 months warranty after shipment. Generally, we offer 12 months for FREE maintenance. while considering sea transportation, we can extend 2 months for our customers.

Moreover, If your machine doesn't work, you can send us an e-mail or call us we will try our best to find the problem through our conversation or by video chat if necessary. Once we have confirmed the problem, the solution will be offered within 24 to 48 hours.

2. What about the delivery term?

For our standard machine which means normal machines, If we have stock in the warehouse, is 3-7 working days;

If there is no stock, normally, the delivery time is 15-20 working days after payment received;

If you are in urgent need, we will make a special arrangement for you.

3. Do you accept customization services? Can I have my logo on the machine?

Yes, of course. We can not only offer standard machines but also customized machines according to your requirements. And we can also put your logo on the machine which means we offer OEM and ODM service.

4. How can I install and use the machine?

Once you have ordered the testing machines from us, we will send you the operation manual or video in English version through Email.

Most of our machine is shipped with a whole part, which means it is already installed, you just need to connect the power cable and start to use it. And if it's necessary, we can also assist you to install your machine on site.

Prev: OLABO CHINA Touch Screen Constant

Next: Superior Materials Electronic Environment Steam Aging Testing Chamber

Our Contact

Send now