UV Lamp Aging Test Chamber

The UV lamp aging test chamber stimulates dew and rain with condensation for humidity and / or water spray equipped with

Description

Basic Info.

| Model NO. | ZH-UV-263 |

| Types | Case Typed / Tower Typed |

| Applications | School, Hospital, Lab, Factory |

| Service | OEM / ODM / Non-Standard Available |

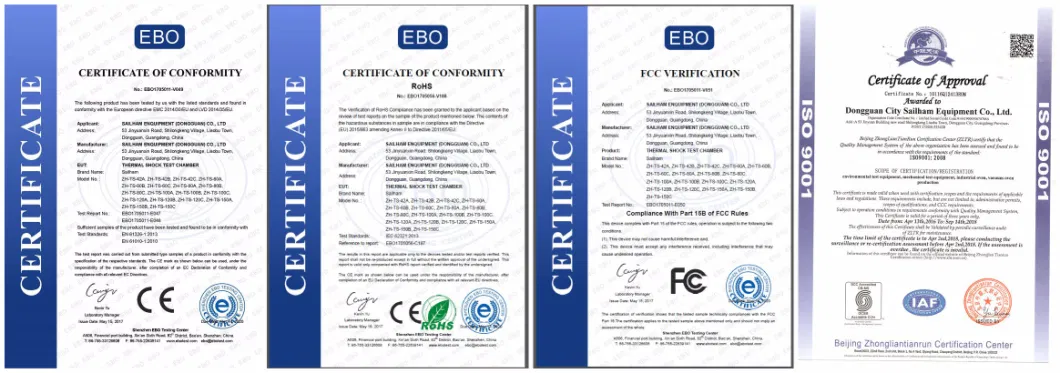

| Certification | Ce, RoHS, FCC, ISO, SGS Certificates |

| Transport Package | Wooden Case for Export |

| Specification | Customization available |

| Trademark | Sailham |

| Origin | Guangdong, China |

| HS Code | 8479899990 |

| Production Capacity | 5000sets/Year |

Product Description

The UV lamp aging test chamber stimulates dew and rain with condensation for humidity and / or water spray equipped with a fluorescent UV lamp which can completely simulate the UV spectra of sunlight, exposes materials to alternating cycles of UV light and moisture at controlled, elevated temperatures. It's most widely used to test types of damages outside that need several months or several years reapear, damages include colour change, gloss loss, chalking, cracking, crazing, hazing, blistering, strength loss and oxidation, the machine only need several days or several weeks. The source adopts 8 pieces of UV lamps of 40W as the light source. The lamps are distributed on the two sides of machine, 4 pieces for each side (UVA-340 and UVB-313 optional). It makes the material damages under the sun (UV), rain (spray) reapear fastly and truly.Application: paints, coating & inks, plastic, printing package, aluminium material, adhesive, auto & motorcycle, cosmetic, metal, electronic, electroplate, pharmaceuticals and so on.

Function:

- The UV Accelerated weathering Test Chamber simulates effects from outside humidity;

- Test exact temperature by black panel temp. sensor, it can repeat the tested result;

- Cycling test for humidity, condensation, and spray available;

- Calibrator resource and auto calibrated program for the radiancy;

- Test samples: 24pcs for each at 75mm*300mm, 48pcs for each at 75mm*150mm (for Tower-type only).

- ASTM D4329

- ISO 4892-3

- ISO 11507

- SAE J2020,

- GB/T14552-93

- GB/T16422.3-1997 GB/T16585-96

- GB/T16585-1996

- GB/T16422.3-1997

| Model | ZH-UVA-115 (Case-type) | ZH-UVA-263 (Tower-type) |

| Inner size | W1170*H450*D500mm | W1170*H450*D500mm |

| Inner size | W1350×H1480×D650mm | W1300 X H1450 x D550mm |

| Temperature range | RT~70°C | |

| Temperature uniformity | ±1°C | |

| Temperature fluctuation | ±0.5°C | |

| Testing time | 0~999H, adjustable | |

| Materials | Inside and Outside SUS#304 stainless steel | |

| Humidity range | ≥90%RH | |

| Controller | Taiwan TATO programmable controller (Both in Chinese and English), LCD touch screen | |

| Lamp power | 40W/Piece | |

| Test cycle setting | Illumination, condensation and water spray test cycle is programmable | |

| Irradiance | 1.1W/cm2 | |

| Ultraviolet light | UV-A: 315-400nm; UV-B: 280-315nm (8pcs, 1600h lifetime); 8 pieces of Atlas Lamp, length: 120cm | |

| Distance between lamps | 35±2mm (adjustable) | |

| Distance from samples to lamp | 50±2mm (adjustable) | |

| Centre distance between the lamp | 70mm±15mm | |

| Standard Specimen Size (for tower-type only) | 75×150mm or 75×290mm (special requirements to be described in the contract) | |

| Required water depth for water channel | 25mm, automatically control | |

| Protection system | Overload short circuit protection, over temperature protection, water lack protection, Earth leakage protection, Auto shut off protection | |

| Power | 220V/50Hz /±10% 4.5KW | |

Product structure:

Wooden case packing for export:

Contact us at:

Company Address: Room 1605A, Ho King Commercial Centre, 2-16 Fa Yuen Street, Mongkok, Kowloon, Hong Kong

Factory Address: NO.53, Jinyuanxin Rd, Shilongkeng, Liaobu Town, Donggaun, Guangdong China (Mainland).

Prev: Rapid Temperature Change Environmental Test Chambers Humidity Chamber

Next: Asli Top Brand Rapid Rate Temperature Change Test Chamber

Our Contact

Send now