Professional Manufacturers 2 Zone Thermal Shock Test Chamber with Factory Price

Description

Basic Info.

| Circulation System | Multi-Lobe Centrifugal Wind Turbine |

| Sensors | Platinum Resistance. PT100Ω/Mv |

| Insulation Material | Polyurethane Rigid Foam/Ultrafine Glass Fiber Wool |

| Humidity Deviation | 2-3%Rh |

| Inner Material | SUS304 Stainless Steel |

| Usage Environment Temp | 5ºC~+30ºC ≤85%R.H |

| Humidity Fluctuation | ±2%Rh |

| Humidity Range | 20%Rh-98%Rh |

| Cooling Rate | 0.7ºC/Min-1ºC/Min |

| Keyword | Temperature Humidity Test Chamber |

| Temperature Range | -70ºC-150ºC |

| Temperature Overshoot | ≤±2ºC |

| Heating Rate | 1ºC/Min-3ºC/Min |

| Transport Package | Export Wooden Cases |

| Specification | 1000*1000*1000mm |

| Trademark | NOKI |

| Origin | China |

| HS Code | 8479899990 |

| Production Capacity | 20set/ Month |

Product Description

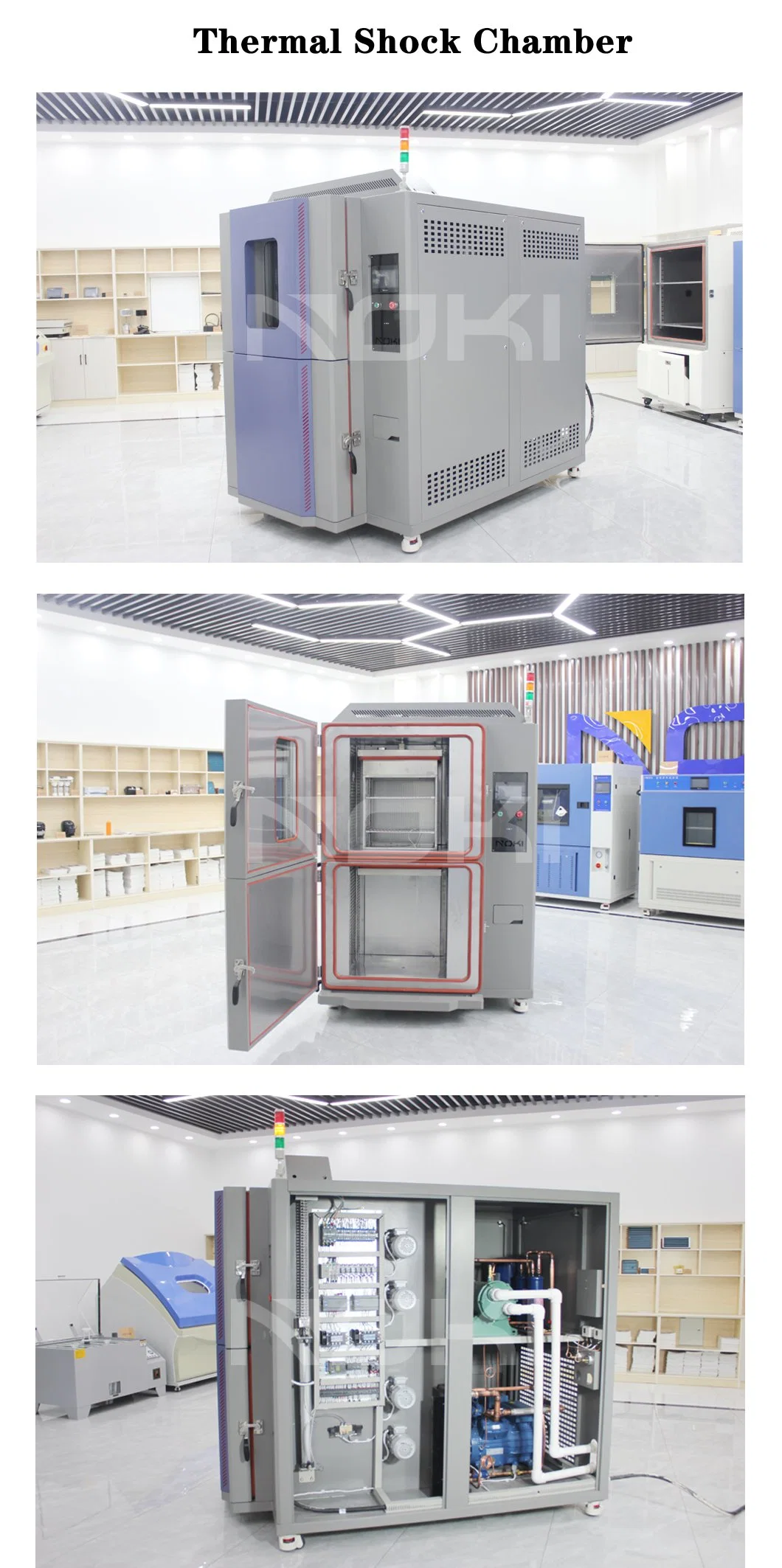

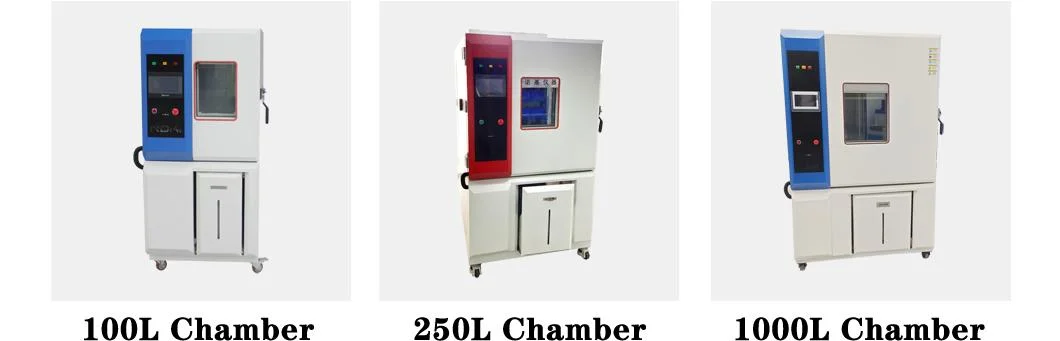

Thermal Shock Chamber

The thermal shock chamber is material such as metal, plastic, rubber, electronics industry the necessary test equipment, used for testing or composite material structure, in an instant by extremely high temperature and low temperature under continuous environment to endure, to test samples in the shortest possible time for heat bilges cold shrink caused by chemical or physical damage.Hot cold thermal test chamber to meet the test method: GB/T2423.1.2. GB/T10592-2008. GJB150.3 high and low-temperature impact test.The high low temperature thermal test chamber is divided into three chambers and two chambers according to the test requirements and test standards, the difference lies in the test method and the different internal structures.The three-chamber type is divided into a cold storage chamber, a heat storage chamber and a test chamber, where the product is placed during the test.The two-box type is divided into a high and low temperature chamber, which is driven by a motor to switch between high and low temperatures, and the product is placed in the basket, which moves with the basket.

High low temperature test chamber

High low-temperature test chamber: suitable for high low-temperature reliability test of industrial products. It is similar to the Thermostatic humidity chamber but without humidity functions.This test chamber only simulates a temperature environment, with higher heating and cooling rate, basically the speed can be 3ºC per min, 4ºC per min, 5ºC per min, or 10ºC per min depending on the customer.The environmental test chamber has a wide range of temperature control, for example, temp range from -20 to +150. or 0 to +100.

Product Details

Product Introduction

Noki constant temperature and humidity chamber can simulate high temperature, low temperature, alternating humidity, and heat or constant temperature environment to test the samples.

Pharmaceutical Stability Test ChamberThe pharmaceutical grade stability test chamber is suitable for the new meds stability test and verification of meds and new meds in pharmaceutical enterprises and meds research institutes.The common Thermostatic humidity chamber can do the same, but there is huge differences between the standard pharma using test chamber and humidity chambers.It is designed and manufactured according to Chinese Pharmacopoeia Appendix XIX C Guiding Principles of meds stability test and GB/T10586-89. and scientifically simulates a long-term stable working temperature, humidity, and light environment required for meds failure evaluation, which is a piece of necessary equipment for pharmaceutical enterprises to pass GMP certification.

Walk-in Environmental Test Chamber

A Walk-in test chamber is one of the important pieces of testing equipment in the product development and testing stage.

The walk-in environmental test chamber is mainly used to test the tolerance of products to the external environment and the performance of long-term exposure to the natural environment, so as to optimize the defects of products and detect the use of the production environment and service life.

The environmental testing chamber is often used for heat and cold resistance testing of the national defense industry, aerospace industry, auto parts of automatic components, electronic and electrical parts, plastics, chemical industry, pharmaceutical industry, and related products.

Exhibitiom

Certifications

Calibration

The equipment will be tested, debugged, calibrated before delivery with test report, when customer received the chamber ready for use.

Packaging & Shipping

- Waterproof plastic film

- Buffer foam is placed in the four corners of the chamber

- Standard wood export packaging.

- Can be used for sea, air, railway, truck, etc.

After Sales Service

- After-sales service commitment: user satisfaction is our service purpose, perfect after-sales service to relieve you of all worries, we firmly believe that a good business sold not only a good product, importantly a better service.

- 1-year free warranty lifelong service. (except consumables and wearing parts)

- During the warranty period, we will regularly give feedback on the use of the product and help users solve technical problems and maintenance.

- Purchase other accessories, only the material costs, processing fees

- After the warranty period, equipment fault can be instructed by telephone or by courier has been bad parts for replacement, Noki does not charge labor and management costs, only travel expenses (if we need to visit the workshop), or the cost of materials.

Prev: Ce Certificated UV Light Aging Test Chamber

Next: Automatic UV Accelerated Aging Test Chamber with LCD Touch Screen for Plastic

Our Contact